Nzira yekugadzira yeTerry Fabric Circular Knitting Machinesinoteedzana yakaomesesa yematanho akagadzirirwa kugadzira emhando yepamusoro terry machira. Aya machira anoratidzirwa nemaitiro avo akasungwa, ayo anopa yakanakisa absorbency uye kugadzirwa. Heino kutarisisa kwakadzama kwemaitiro ekugadzira:

1. Kugadzirira kwezvinhu :

Yarn Sarudzo: Sarudza shinda dzemhando yepamusoro dzakakodzera kugadzirwa kwemachira eterry. Sarudzo dzakajairika dzinosanganisira donje, polyester, uye mamwe mafivha ekugadzira.

Yarn Kudyisa : Rongedza shinda pane creel system, kuve nechokwadi kugadzikana kwakaringana uye kurongeka kudzivirira kuputika uye kuve nechokwadi chekudya chinoenderana.

2. Machine Setup :

Needle Configuration : Gadzira tsono maererano neinodiwa geji yejira uye pateni. Terry knitting michina inowanzo shandisa latch tsono.

Cylinder Adjustment: Gadzirisa silinda kune iyo dhayamita chaiyo uye ive nechokwadi kuti yakanyatsoenderana neinonyura mhete uye cam system.

Cam System Calibration: Calibrate iyo cam system kudzora kufamba kwetsono uye kuzadzisa yaunoda stitch pateni.

Yarn Kudyisa : Iyo shinda inodyiswa mumushini kuburikidza neshinda inodyisa, iyo inodzorwa kuchengetedza kusagadzikana kunoenderana.

Needle Operation : Sezvo silinda inotenderera, tsono dzinoita zvishwe mumucheka, dzichigadzira jira. Sinkers inobatsira kubata uye kusunungura zvishwe.

Loop Formation: Special sinkers kana crochet tsono dzinorebesa sink arc ye loop yarn kuti iite zvishwe.

4. Kudzora Hunhu :

Real-time Monitoring : Michina yemazuva ano yakashongedzerwa neyepamberi yekutarisisa masisitimu anoteedzera density yejira, elasticity, kutsetseka, uye ukobvu munguva chaiyo.

Otomatiki Kugadziridza: Muchina uyu unogona kugadzirisa otomatiki maparamita kuti uchengetedze hunoenderana jira remhando.

5. Post-kugadzirisa :

Mucheka Tora-pasi: Mucheka wakarukwa unounganidzwa uye unokuvadzwa pabatch roller. Iyo yekutora-pasi system inoita kuti jira rakuvadzwa zvakaenzana.

Kuongorora uye Packaging: Iro jira rakapedzwa rinoongororwa kuti harina here uye rozoiswa mukati kuti riendeswe.

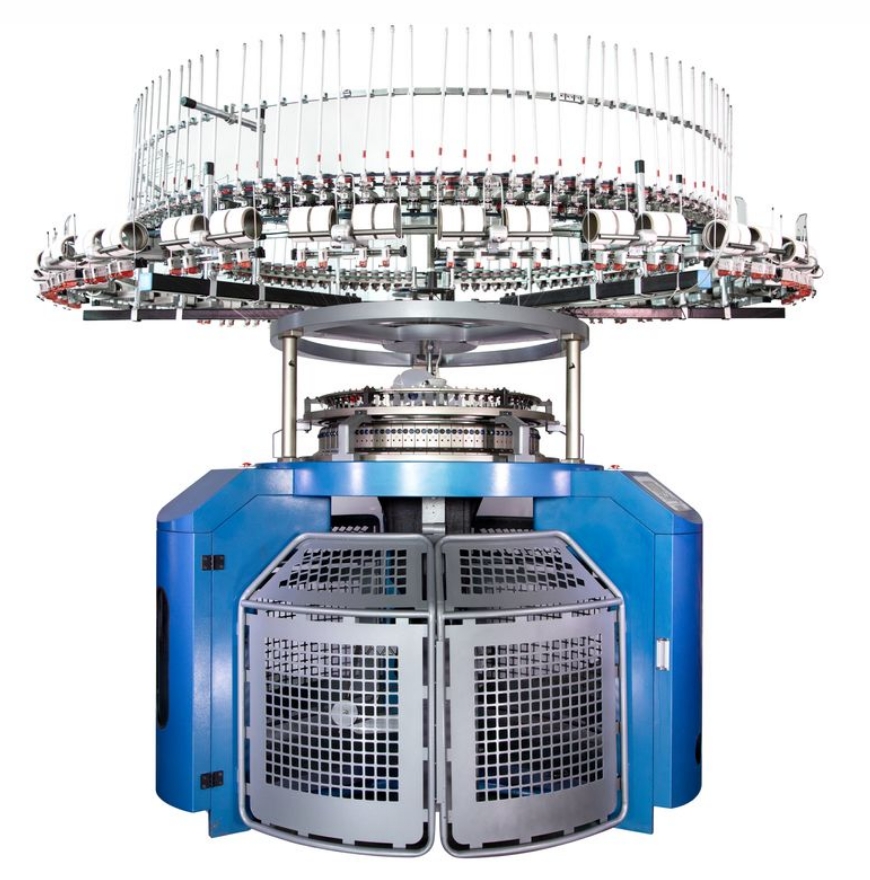

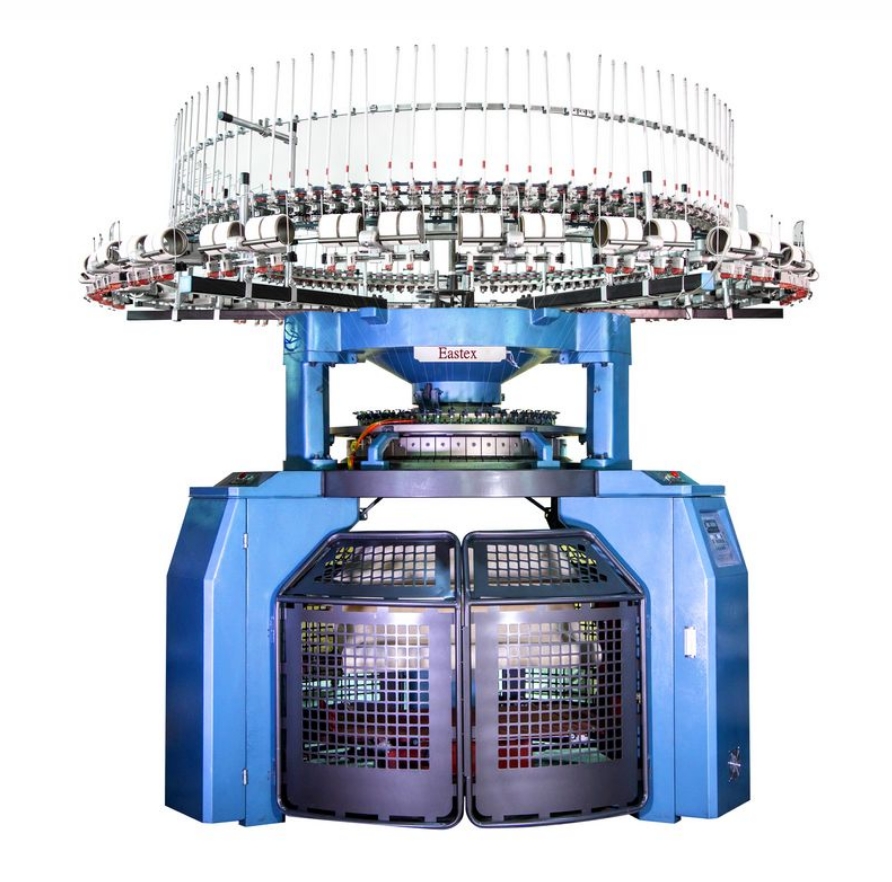

Zvikamu uye Mabasa Azvo

1. Mubhedha wetsono:

Cylinder uye Dial : Silinda inobata hafu yepasi yetsono, nepo dial inobata hafu yepamusoro.

Needles : Latch tsono dzinowanzo shandiswa kuita kwavo kuri nyore uye kugona kugadzira akasiyana marudzi eshinda.

2. Yarn Feeders :

Yarn Supply : Aya mafeeder anopa shinda kune tsono. Izvo zvakagadzirirwa kushanda nemhando dzakasiyana-siyana, kubva kune yakanaka kusvika kune yakawanda.

3. Cam System :

Stitch Pateni Kudzora: Iyo cam system inodzora kufamba kwetsono uye inosarudza iyo yekusona pateni.

4. Sinker System:

Loop Holding : Sinkers inobata zvishwe panzvimbo iyo tsono dzichikwira kumusoro uye pasi, dzichishanda pamwe chete netsono kuti dzigadzire iyo yaidiwa stitch pattern.

5. Fabric Take-up Roller :

Mucheka Wekuunganidza : Iyi roller inokwevera jira rakapedzwa kubva pamubhedha wetsono uye inoipeperetsa pamupumburu kana kuti spindle.

Configuration

Terry Fabric Circular Knitting Machineshuya mumagadzirirwo akasiyana siyana kuti asangane nezvinodiwa zvekugadzira zvakasiyana. Zvirongwa zvakakosha zvinosanganisira:

Single Needle Bed Multi-cam Type : Rudzi urwu runoshandiswa zvakanyanya pakuita kwayo uye kugona kugadzira akasiyana loop kureba.

Kaviri Needle Bed Circular Weft Machine : Modhi iyi inoshandisa mibhedha miviri yetsono kugadzira zvishwe zvehurefu hwakasiyana.

Kuisa uye Kutumwa

1. Kutanga Setup :

Kuiswa kweMuchina: Ita shuwa kuti muchina waiswa panzvimbo yakagadzikana uye nhanho.

Simba uye Yarn Supply: Batanidza muchina kune sosi yemagetsi uye gadzira iyo yarn yekugovera sisitimu.

2. Calibration:

Tsono uye Sinker Alignment: Gadzirisa tsono uye sinkers kuti uve nechokwadi chekuenderana.

Yarn Tension : Calibrate the larn feeders kuti uchengetedze kuwirirana kunoenderana.

3. Test Inomhanya :

Sample Production: Mhanya muchina neshinda dzekuyedza kugadzira machira emuenzaniso. Ongorora masampuli ekuona kuenderana kwemisono uye kunaka kwemachira.

Adjustments : Ita chero zvigadziriso zvinodikanwa zvichibva pane zvakabuda mubvunzo kuti uve nechokwadi chekushanda kwakakwana.

Kugadzirisa uye Mushure-Kutengesa Sevhisi

1. Regular Maintenance :

Kucheneswa Kwezuva Nezuva: Chenesa kumusoro kwemuchina uye shinda yeshinda kubvisa marara nemafibhi.

Vhiki Kuongorora: Tarisa michina yekudyisa shinda uye kutsiva chero nhengo dzakasakara.

Monthly Cleaning : Nyatsochenesa dial uye silinda, kusanganisira tsono uye sinkers.

2. Tsigiro yehunyanzvi:

24/7 Tsigiro: Vazhinji vagadziri vanopa kutenderera-the-wachi rutsigiro rwehunyanzvi kubatsira kune chero nyaya.

Warranty uye Kugadzirisa: Yakazara waranti yekuvhara uye nekukurumidza kugadzirisa masevhisi aripo kuti aderedze nguva.

3. Kudzidzira :

Operator Kudzidziswa: Kudzidziswa kwakazara kwevashandisi pamushini mashandiro, kugadzirisa, uye kugadzirisa dambudziko kunowanzo kupihwa.

4. Kuvimbiswa Kwemhando:

Kuongorora Kwekupedzisira: Muchina wega wega unoongororwa kwekupedzisira, kuchenesa, uye kurongedza usati watumirwa.

CE Kumaka: Machina anowanzo kucherechedzwa CE kuti ave nechokwadi chekuti anosangana nemhando yepamusoro yekuchengetedza uye kuita.

Mhedziso

Terry Fabric Circular Knitting Machinesmaturusi akakosha muindasitiri yemachira, anokwanisa kugadzira emhando yepamusoro terry machira ekushandisa kwakasiyana. Maitiro ekugadzira anosanganisira kungwarira kugadzirira zvinhu, chaiyo yekumisikidza muchina, kuenderera kuruka, kutonga kwemhando, uye post-kugadzirisa. Michina iyi inoshanda zvakasiyana-siyana uye inowana maapplication mune zvipfeko, machira epamba, uye machira ehunyanzvi. Nekunzwisisa maitiro ekugadzira, zvikamu, zvigadziriso, kuisirwa, kugadzirisa, uye mushure mekutengesa sevhisi, vagadziri vanogona kukwidziridza mashandiro avo uye kusangana nezvinodiwa zvakasiyana zvemusika wemachira.

Nguva yekutumira: Kubvumbi-08-2025